Return to the

Back Creek Diary

38

Special Wadcutter – Questions & Answers

©

2014 - Ed Harris

38 Special Double Ended Wadcutter

Cost

is a matter of demand and volume. Back in the day when all the police

departments carried .38 Specials and used wadcutters for training and practice

the ammo factories loaded wadcutters by the millions of rounds. Before about

1980 police departments didn't require use of full duty ammo for qualification

so .38 wadcutters were widely used for practice, qualification and NRA police

revolver competition. Before about 1980 the .38 Special was also commonly used

during the center-fire stages of conventional NRA style bullseye shooting, by

both civilians and the military teams at Camp Perry, so there was high demand

for quality ammo produced in large volume.

The military marksmanship units used to sample, test and then buy the very best

lots by the truckload. Civilian customers got the leftovers. I can remember in

the 1970s testing all popular brands of factory wadcutters off a machine rest

in an indoor tunnel. It was no trouble to select lots which would shoot

10-shots groups averaging an inch and a half at 50 yards. The best stuff

Remington-Bridgeport used to make would hover close to an inch from a heavy

test action and return-to-battery rest. Today I use a single-shot target rifle

with Unertl scope to test .38 ammo. Years ago it was impossible to handload

wadcutter which was as good as the best factory stuff. Today it is hard to find

factory wadcutters that average under 2 inches. I can do that well with

carefully cast Saeco double-enders assembled on a Dillon RL550B. A lot of

factory wadcutter you buy today won't do better than 3 inches, which is no

better than you expect with ordinary +P service ammo.

This is because today very few people buy wadcutters for serious match work

anymore. Conventional bullseye and PPC revolver sports don't have the large

following they once did. Most wadcutter ammo sold today is used for basic

training in CCW classes and sold to people who want to practice with a lower recoil

load in their .38 snubbie at 7 yards, so the only requirement is for the ammo

to go BANG!

Because factories don't load wadcutter constantly, but only to fill orders as

needed, with reduced demand, and no pressure from customers for quality ammo,

in smaller volume it costs more and it isn't as good as the old stuff you

bought 25 or more years ago.

Of the available soft swaged HBWC bullets available

today Remingtons are the best hands down. They fully equal the fine old

Winchester bullets you used to be able to get.

With current Alliant Bullseye it takes 3.0-3.2 grs. to reach the same velocity

you would expect to get with factory wadcutter loads. But accuracy deteriorates

with the Hornady, Speer or Precision-Delta HBWC bullets if you try to load over

2.8 grs. for 720+/- 30 f.p.s.

The former Hercules Bullseye powder took only 2.7-2.8 grains to develop 750 +/-

30 f.p.s. from a 6-inch PPC gun with a flush-seated 148-gr. bullet, but that

gets you only about 700-720 f.p.s. with current product which may not be enough

to stabilize the bullet in 18-3/4 inch twist S&W's or to reliably function

the S&W Model 52 or Colt Gold Cup with the standard factory recoil spring.

With TiteGroup there is some lot-to-lot variation, so start at 2.4 grs. and

adjust as needed for reliable function and velocity 750+/- 30 f.p.s. for the

blowback-operated match pistols. The Remington bullets will stand up to 3.5

grs. of Alliant Bullseye for 850 +/- 30 f.p.s. without the skirt opening up or

hurting accuracy if the revolver forcing cone is properly cut. This load can

also be used in the Colt Gold Cup as a good field load if you use the

full-power 16 pound .38 Super recoil spring.

SAECO

#348 Double Ended Wadcutter

I use the Saeco #348 double-end, bevel-base wadcutter

cast 10-11 BHN using indoor range backstop scrap. As-cast bullet diameter is

.360", the same as factory Remington 148-grain HBWCs. I load these as-cast

and unsized, lubricating with Rooster jacket full strength in a proportion of

1/3 cup to 1000 bullets, or alternately using a diluted solution of Lee Liquid

Alox cut 50-50 with mineral spirits in the same ratio. Both lubes work just as

well for target loads, but if you change lubes you must thoroughly clean and

dry the barrel and chambers of the cylinder and recondition the bore by wiping

with a patch lightly wet with lube, letting it dry, and then wiping with two

dry patches.

Cast double-end wadcutters require heavier charges to shoot well than

soft-swaged hollow base types. I load 3.5 grains of Alliant Bullseye with

Remington 1-1/2 primers for double-end wad-cutters and 3.1-3.2 grs. with

factory Remington HBWC bullets. I load the Remington bullet flush seated

similar to factory loads and the Saeco #348 double-end bullets with their

sprue-cut forward, to the crimp groove with the beveled base band exposed. I

taper crimp using the Lee Factory Crimp Die applying no more crimp than is

necessary to completely remove any mouth flare. Excessive crimp damages the

bullets and enlarges groups.

Loading

the SAECO #348 Double Ended Wadcutter (.38 Special)

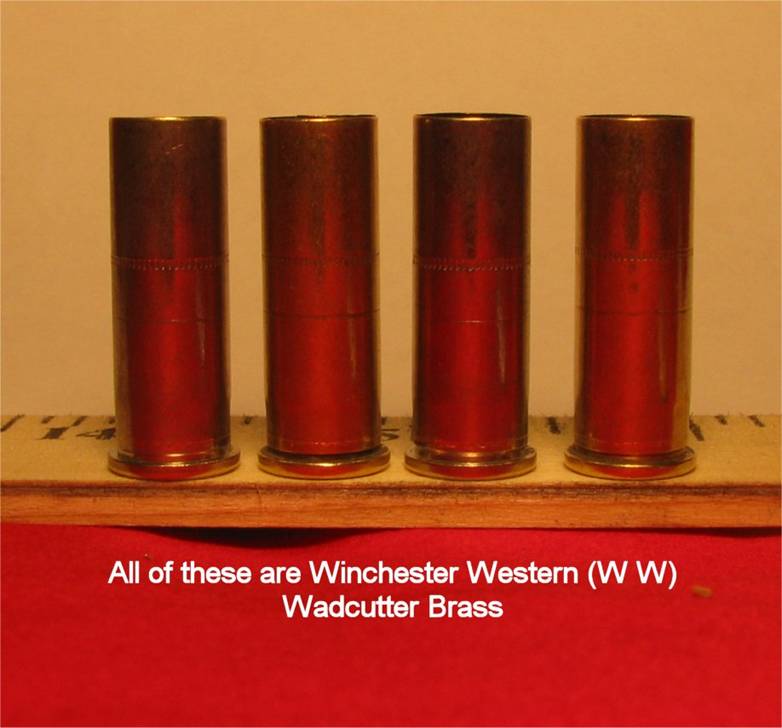

For serious target work I use only cases which were

originally used for loading factory wadcutter ammunition. Wad-cutter brass has

thinner walls with a long cylindrical section which extends all the way to the

seated base of the wadcutter bullet, whereas +P and other cases made for JHP

service loads are thicker walled and have a faster internal taper intended to

increase bullet pull to improve ballistic uniformity with the slower powders

used for factory loading jacketed service loads.

If

your target revolver or match auto pistol has tight chambers, cases expand very

little so that .360 diameter bullets will hold friction tight in fired brass

until the shell head on the loading machine rotates to the final station in

which rounds should be full-length profiled and taper-crimped only enough to

remove all mouth flare. Unless your gun has sloppy service chambers, it will be

necessary to resize the brass to prevent bullets from dropping down against the

powder under vibration of the loading machine, which causes DANGEROUS

variations in seating depth!

By loading the "fat" factory Remington bullets or as-cast bullets in

unsized brass, and profile taper-crimping in this manner, case life is

improved, bullet deformation is reduced and bullet pull is more uniform,

because the brass work hardens and springs back much less when it is worked

only once in profile crimping, versus when being cold worked three times in the

usual method of full length resizing, expanding, seating and crimping.

Standard .38 Special loading dies work brass excessively because their

dimensions are intended to resize cases tightly enough to provide a tight

bullet fit with jacketed bullets. If you must load new brass or that which has

been previously resized use a .38 S&W Cowboy Expander plug of .358" to

reduce bullet base deformation during seating.

My loading method is to separately de-cap brass, tumble clean in clean corncob,

uniform primer pockets using a carbide tool with fixed depth stop, deburr flash

holes with a No. 2 long center drill the first time they are loaded, then hand

prime brass so primers are always seated carefully by feel in a clean pocket. I

use the Dillon RL550b for load assembly to flare case mouths, measure powder,

seat bullets and crimp. I use this same simplified process in loading .45 ACP

my match ammo as well.

Using the Lee Factory Crimp die sizes the bullet only if needed to ensure that rounds

do not exceed SAAMI Maximum cartridge dimensions. It does so by gentle

compression f the bullet inside the case instead of reducing it by radically

shear in a die. The un-sized, exposed bevel band of the DEWC ahead of the case

mouth enables a positive gas seal in revolver cylinder throats. My .38 Special

wadcutter reloads average sub 2-inch 5-shot revolver groups at 50 yards from

Ransom Rest in long series of targets. It takes a very good lot of factory

wad-cutters to beat this.

Q- I am setting up to cast

bullets for my Colt Officers Model Special .38 Special. I have slugged the

bore, which measures .3545. The ball end chamber on one chamber measured 356,

the others .357, so what size should I size the bullets to?

A - ALWAYS size cast bullets to fit

the diameter of the cylinder throats. When bullets are sized correctly you

should feel resistance in pushing a bullet when inserted from the rear of the

chamber and pushing it out the front, but you should be able to do so using

hand pressure only. If bullets cannot be readily pushed through by hand, it

raises chamber pressure and causes leading in the cylinder. If bullets readily

fall through and out the front of the cylinder of their own weight, this causes

forcing cone leading and poor accuracy due to asymmetrical bullet case

deformation.

If one chamber is tight, and the others are large, the best solution is to lap

out or ream the tight chamber to match the others. If you do not want to modify

the gun, then mark the tight chamber and don't use it.

If bullets are sized to fit the one tight chamber, they will fit too loosely in

the others and shoot loose groups. Bullets which fit properly in five chambers

and which fit too tightly in the one tight give you an

otherwise "good group" with a flier.

In my 1959 Colt Officers Model Match revolver I use the Saeco #348 double-end,

bevel-base wadcutter cast 10 BHN using indoor range backstop scrap. As-cast

bullet diameter is .360", which is the same as factory Remington 148-grain

HBWCs. I load these as-cast and unsized, lubricating with Rooster jacket full

strength in a proportion of 1/3 cup to 1000 bullets, or alternately using a

diluted solution of Lee Liquid Alox cut 50-50 with mineral spirits in the same

ratio. Both lubes work just as well for target loads, but if you change lubes

you must thoroughly clean and dry the barrel and chambers of the cylinder and

recondition the bore by wiping with a patch lightly wet with lube, letting it

dry, and then wiping with two dry patches.

Double-end wadcutters require heavier charges to shoot well than hollow base

types. I load 3.5 grains of Alliant Bullseye with Remington primers for

double-end wad-cutters and 3.1-3.2 with factory Remington HBWC bullets. With

the Saeco #348 I seat bullets sprue-cut forward, with the beveled base band

exposed. I taper crimp using the Lee Factory Crimp Die applying no more crimp

than is necessary to completely remove any mouth flare. Excessive crimp damages

bullets and enlarges groups.

For serious target work use cases which were originally used for loading

factory wadcutter ammunition. Wad-cutter brass has thinner walls with a long

cylindrical section which extends all the way to the seated base of the

wadcutter bullet, whereas +P and other cases made for JHP service loads are thicker

walled and have a faster internal taper intended to increase bullet pull to

improve ballistic uniformity with the slower powders used for factory loading

jacketed service loads.

If your target revolver has tight chambers, as mine does, so that fired cases

expand very little, .360 diameter bullets seat and hold friction tight in fired

brass until the shell head on your loading machine moves to the final station

in which rounds should be full-length profiled and taper-crimped.

With a close chambered target revolver or autoloader, it is unnecessary to

resize brass. By loading as-cast bullets in unsized brass, and profile

taper-crimping in this manner, case life is improved, bullet deformation is

reduced and bullet pull is more uniform, because the brass work hardens and

springs back much less when it is worked only once in profile crimping, versus

when being cold worked three times in the usual method of full length resizing,

expanding, seating and crimping.

Standard .38 Special loading dies work brass excessively because their

dimensions are intended to resize cases tightly enough to provide a tight

bullet fit with jacketed bullets. If you must load sized brass use a .38

S&W Cowboy Expander plug of .358" to reduce bullet base deformation

during seating.

But with a target revolver having correct chambers it is unnecessary to resize

fired brass. My loading method is to separately de-cap brass, tumble clean,

uniform primer pockets, deburr flash holes and hand prime brass so primers are

always seated carefully by feel in a clean pocket. I then use the Dillon RL550b

for final load assembly to flare case mouths, measure powder, seat bullets and

crimp. I use this same simplified process in loading .45 ACP my match ammo as

well.

Using the Lee Factory Crimp die sizes the bullet only if needed to ensure that

rounds do not exceed SAAMI Maximum cartridge dimensions. It does so by gentle

compression f the bullet inside the case instead of reducing it by radically

shear in a die. The un-sized, exposed bevel band ahead of the case mouth

enables a positive gas seal in revolver cylinder throats. My .38 Special

wadcutter reloads average sub 2-inch 5-shot groups at 50 yards in long series

of targets. It takes a very good lot of factory wad-cutters to beat this.

Return to the

Back Creek Diary