Return to the Back Creek Diary Making serviceable .25-35 brass from .30-30s

© 2014 – Ed Harris

Frank Marshall’s and my friend Bill has a long-barreled 1894

Winchester with octagon barrel chambered in .25-35 WCF. It was made in 1908 and helped feed his

family when he was a kid in Montana during the Depression. That rifle killed everything from grouse to

elk. These days Bill doesn’t deer hunt,

but he wanted to get re-acquainted with his old friend and asked me to help

work up some small game and recreational loads.

We learned a few things in doing so, and I thought we should share for

anyone with a .25-35 who wants to feed it economically.

Factory .25-35 loads feature a 117-gr. soft-point bullet. Some

50-year-old Super-X rounds Bill had and current Winchester ammo chronographed

just shy of 2300 f.p.s. from his 26 inch barrel. Factory loads are expensive and not sold at

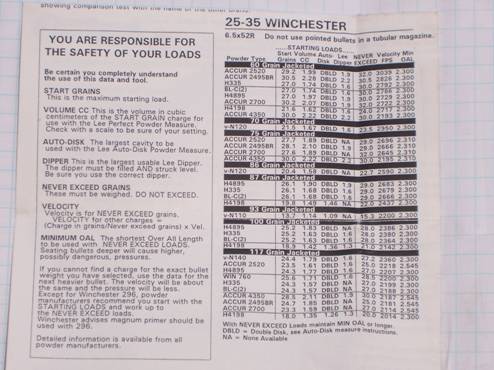

Wal-Mart. The Lee data table which came

with Bill’s die set lists 20 grains of 4198 with the

117-gr. Hornady. This shot very well and chronographed about 2100 f.p.s. No deer around our woods here is likely to

know the difference.

Lee Data Table:

Bill says that the .25-35 is the most accurate chambering in the Winchester 94

because its small bore makes for a heavier, more rigid barrel. Its 8-inch twist

handles quiet, subsonic cast bullet loads very accurately, while getting great

penetration because they auger on through, if not driven so fast they blow up.

You can load as little as 4 grains of fast burning pistol or

shotgun powder with 85-87-gr. lead plain-based bullets. The Meister or RCBS

cowboy slugs drive inch and half groups at 50 yards with iron sights and make

little more noise than a .22 LR, but are more effective. I don’t know whether the factories ever

loaded small game rounds for the .25-35 like they did for the .30-30. But when

hand-loaded with either jacketed or cast lead bullets designed for the .25-20. the .25-35 WCF makes a fine small game cartridge.

I got Bill a set of Lee dies, an RCBS .25-20

Cowboy expander and some Meister 85-gr. flat-nosed .258 bullets

for initial charge establishment. When the Ideal tang sight on his rifle was

zeroed for factory 117-gr. loads at 200 yards, small game loads shot to the

sights at 50 yards and gave inch and half groups. So I decided we should get an

RCBS mould 25-85CM designed for the .25-20. We tried it with equal

results.

Click on Photo for larger pic…

RCBS bullets were cast of wheel weights and shot un-sized in

reworked .30-30 brass. A charge of 5 grs. of SR7625 or 6

grains of PB with 85-87 grain cast bullets approximate the 1300 f.p.s. velocity

of the .25-20. Using 4 grains of

Bullseye gave 1120 f.p.s. and 5 grains of Bullseye gave 1200 f.p.s. The fastest

cast bullet load which shot acceptably was 7 grs. of #2400 for 1420 f.p.s.

We also bought some Remington 85-gr. JSP .25-20 bullets. Firing expansion tests in water jugs

confirmed my memories of factory .25-20 loads. At 1270 f.p.s.

using 8 grs. of PB the soft points perforate

without expansion and penetrate deeply.

Bumping their velocity to 1400 f.p.s. using 10 grains of #2400 expanded

them 0.32 caliber, with no appreciable weight

loss.

But drive these thinly jacketed soft-point bullets much faster

than they were designed to go, and they fragment violently, making a non-ricochet

varmint load. Testing at 50 yards with 14 grs. of #2400 at 1950 f.p.s. on a $0.17 per pound Food Lion meat

manager’s special fryer chicken, pieces of bird were scattered all over

Berkeley County. Neighborhood cats, raccoons and foxes appreciated this, as by

morning even not even a trace was left!

We had the best luck forming cases from Winchester .30-30 brass. I used

Imperial Sizing Die Wax and the die spacer which comes

with RCBS .38/.357 dies to back off the FL sizer for the first pass. This decaps and partially forms the neck and

shoulder, without finishing the case taper..

After pre-forming, case necks are gas annealed.

Then you can full-length resize in a second die pass without buckling

the shoulder. Cases then must be trimmed to length. Lee can provide a custom case length trim

gage to use with their .30-30 cutter and lock stud. You won't need to ream case

neck. As long as brass is formed in two stages with an inter-draw anneal

between you don't lose any. If you try this with Remington or Federal brass you

will wrinkle shoulders on half of the cases. Wrinkled shoulders will work once

for hunting loads which you “Pop and Toss,” but will develop pin holes if you

reload them repeatedly.