The George A. Hensley and “Hensley & Gibbs”

Mould Numbering System

Updated:

04/20/2014

© 2014 - Thomas C. Dugas

This was an

email exchange with Wayne Gibbs in November 2006 on trying to

figure out what the “X” prefix on a mold meant. I had not seen the

“X” prefix

until an eBay

auction showed a X45 mold for sale. So I emailed Wayne and

asked him what

the “X” meant. This is his response:

Okay, Tom,

here's "the rest of the story" (I hope) on our numbering system.

First I should mention that over the years we may have made other attempts

to come up with an intelligent system to designate different bullet designs

and their variations, so there could be some odd-ball designations out there

that I am not familiar with or just don't recall.

George Hensley didn't like the idea of a string of numbers showing the

designated number with the sizing diameter included in it, as it was often

not the actual sizing diameter requested for that particular mold. In other

words "#402429" didn't seem right to him if the mold was made to size

.430",

so he just gave a number to a new design usually in the sequence it was made

up and left it at that. As you know this series jumped around for who knows

what reasons, probably a good one at the time, hopefully, but the reason now

lost to time.

I wrestled with a better system for years, and finally settled on another

less than perfect system-- The design gets an arbitrary number, all it's

own, of course. Then I would add the customer's preference of sizing

diameter that the mold was made for. The problem with that system is that if

the alloy is changed from the original preference it can be sized to a

different diameter, so if the mold was purchased by another person, it would

still be of little use to know the original preferred sizing diameter,

unless the original alloy were known. I couldn't see us stamping something

like "#50BB.358-1-12 ALLOY" on a mold, so gave up on the sizing

diameter

being included.

I finally decided on the last system we used-- the designated design number

and a serial number, which could in turn be traced to the original specs for

that individual mold.

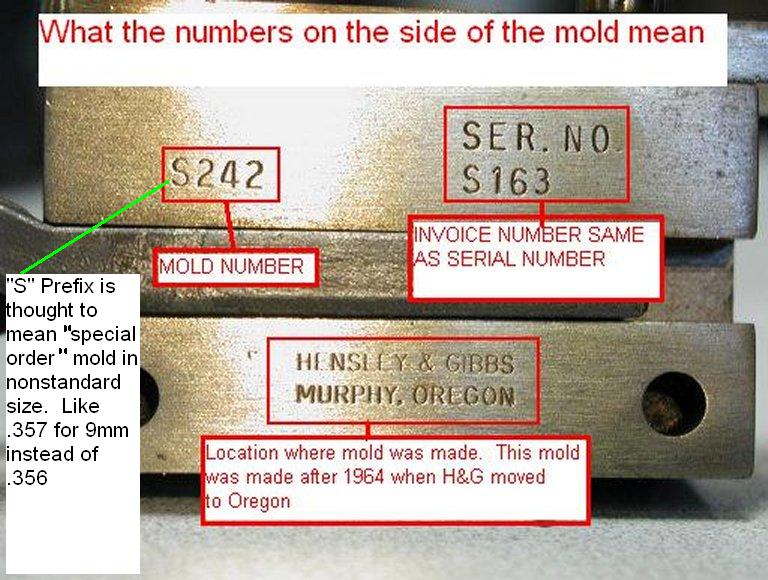

(Note from

me: What Wayne is saying that is on later molds, the serial number

is the same number as the invoice number, and all the notes for that

mold design

were recorded on the invoice. One copy went with the mold to the

customer,

and Wayne kept the other in his factory ledger).

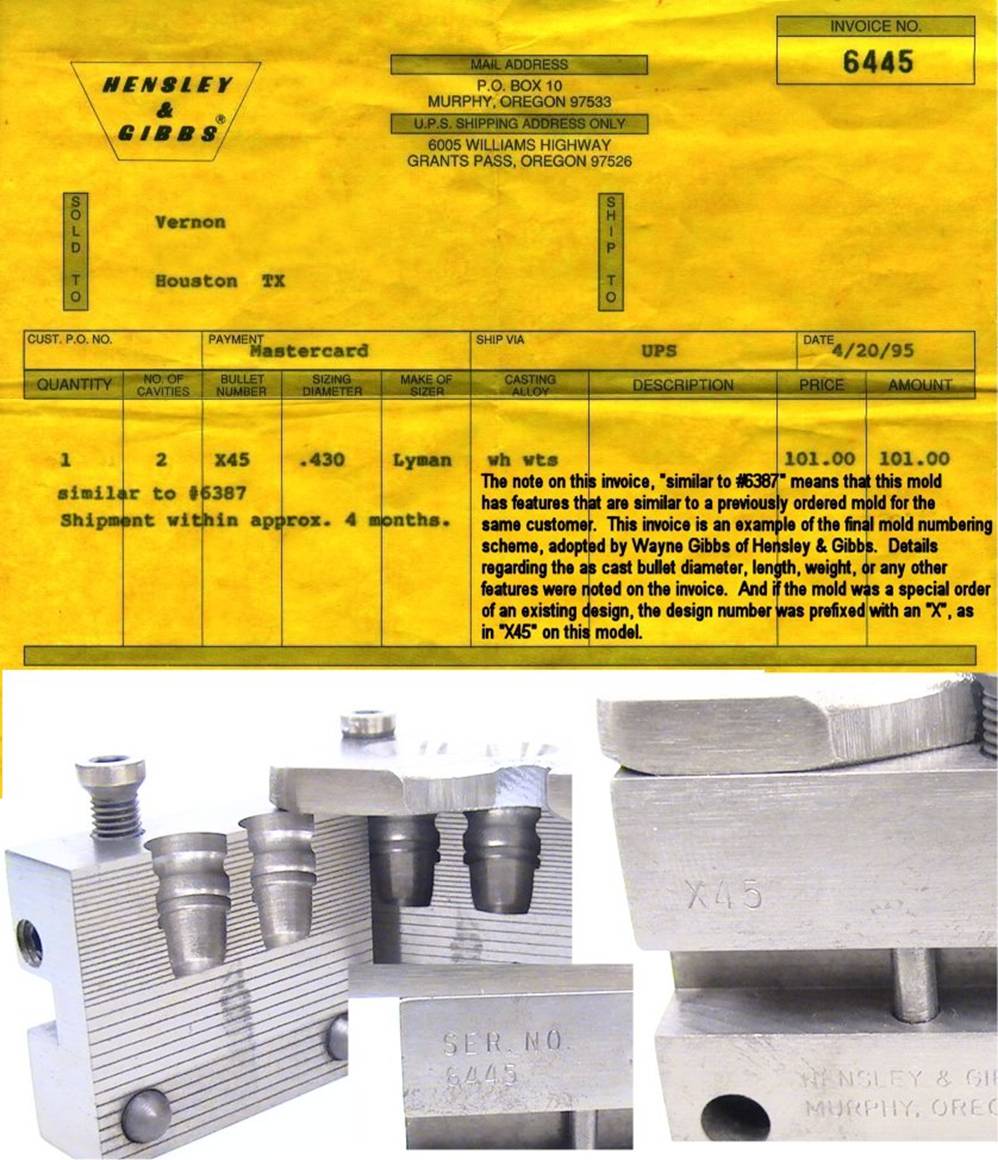

Here is an example of a later invoice.

You can see the invoice number (upper right corner

of below yellow

invoice) matches the mould serial number pictured below the invoice:

Then to the X and S stuff-- We would have a design, say #55 for instance. It

would be for (including) .38 Special. Then someone would come up with the

idea of a design for the .380 Auto. Turns out the #55 would work just fine

if it were simply cut shorter on the base. (Cut shallower in the mold

block). Rather than give the design a whole new number, since it was really

the same bullet but just made to size smaller and be shorter than standard,

they (George and my dad in those days decided these things--(I was just a

"little tad")-- called it "S55" or

S55BB if bevel base. Since this was in

common use, when someone wanted a heavier (longer) base band on #503, for

instance, I called it "#503S" for "special length". I only

designated this

way if there were enough interest in this particular length to make it

"officially" a certain length. In other words if a customer wanted a

"#503S"

it would be cut to this "standard" extended length.

Okay for that, but what if an individual customer thought it would be a

good idea to have a #503 bullet that would cast a slightly lighter bullet

than this extended length S503? --That's where the X came in. X could mean

"experimental" and designate a mold cut not to any specific

pre-designated

length, but to this customer's individual preference, yet clue in another

person that it was not cut standard. You see why most Lyman just shipped

ready-to-purchase molds to stores and you bought it or you didn't? Much

easier to make One-Shoe-Fits-All!

Back to the Hensley & Gibbs

Webpage