Casting for the .218 Bee

By: George Carlson

Not that I always want to do it “The hard way”, but once stuck with the caster’s plague, I have to try and see if I can ring out at least hunting accuracy from whatever gun is at hand with lead bullets that I made myself. Casting and loading for this diminutive cartridge can test the skills of your optometrist. The task of locating a box of loaded 218 Bee ammo in most any sporting goods store is almost impossible. Besides that, when it comes to ammo, I’m plain and simple “CHEAP”. I found some in Cabela’s the other day and they sell them for 46.99 a box of 50, I’m afraid my bills from the heart doctors’ office would be way more!!

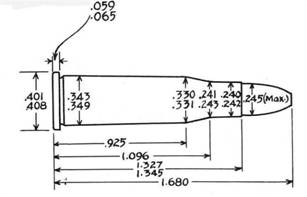

I would suspect that 99% of all the 218 Bee ammo being reloaded these days would be with jacketed bullets. Being an older cartridge with limited sales, you’ll find only a few companies catering to your loading needs. Winchester is the only source for brass unless you want to neck down 25-20 or 32-20’s. Trim length is 1.335. Max is 1.345. Because some tubular magazine rifles have been chambered for the Bee, flat nosed bullets are pushed at you. Don’t let that stop you from trying some pointed bullets. If you’re the type to just target shoot anyway, loading directly into the chamber like a single shot, plus one in the magazine can add to your bullet choices. Fewer of the new load books are publishing much if anything on this cartridge and using new powders means you’ll need to be an extremely good interpolator. A slight adjustment down in the amount of powder you’ve got on hand is what you end up doing using cast verses jacketed bullets. Obtaining sharp edges on those little bases and grease grooves takes you to a different dimension in casting.

A number of handguns and rifles surprisingly are chambered for the Bee, both custom and standard factory. Years ago, there was even a Trapdoor Springfield carbine floating around at our local gun shows with a relined .22 cal barrel. My Deluxe 43 Winchester (Figure 1) is not much more than an oversized rim fire rifle. It’s about the weakest action a 218 was ever chambered for. There are scads of high velocity .22 cal centerfires available if speed is what you need. And above all, remember this is only a 150 yard cartridge.

Figure 1. Model 43 Winchester Deluxe 218 Bee with 10X Unertl

The picture below of .22 designs (Figure 2) is way more than you can expect to come by these days, but modifying the bullets after you’ve cast them the way I do, is one way to add to your chances of finding keeper loads. I found that the bases of the Modern Bond’s were too big to attach any brand of .22 gas check, so I use a Lyman 243 checks. It almost looks like a half jacket bullet. If your shank is long enough, try it with any mould and increase your bullet selection for trials. It sure works for me! The most common 55gr RCBS 22-055-SP that’s still available isn’t in my line up.

Figure 2.

L/R: Hensley & Gibbs #62 Sized with round nose punch, sized nose first, as cast 65gr, Ideal 228367 sized with round nose punch, as cast 62gr, Lyman 225462 55gr, Lee Bator 51gr, Lyman 225415 51gr, Lyman 224450 50gr, Hensley & Gibbs #4 46gr, Ideal 22596 49gr, Modern Bond A-225-525 FN 45gr, Modern Bond A-225-525 HP 44gr both size with .243 gas check, Ideal 225438 43gr, Lyman 225438 41gr.

Finding more than one or two different .22 caliber moulds can be challenging. You really can’t be too choosey. Shying away from an older un-vented or one that has been modified by Bubba with those crude homemade vent lines is sometimes a mistake. Un-vented moulds just need a different technique in casting. Some times the sprue plate fits so tight, you either need to loosen the plate screw a bit, or make a slight bevel edge on the block seams. Taking a small three-sided needle file you open cut an air vent in the top surface of the blocks at the seam where the sprue plate and mould mate. Slowing down the time you pour lead can help also. If you double the time you normally hold the mould to your pot or ladle, it gives a little more time for lead to replace air in those voids that show up on imperfect bullets. That works if you keep your mould temperature up high enough so the melt doesn’t freeze at the sprue plate hole. A thicker sprue plate keeps the temperature up on any mould, so if you’re having problems with bullet frosting because the mould is too hot or you’re not filling out the bullets because you can’t keep the mould temperature up, try changing the sprue plate. I’ve got a big Hensley & Gibbs 450grain 45 caliber double cavity mould that after ten bullets are made gets too hot and bad frost voids show up. I changed to a thinner plate and it cured the problem. Smoking a mould also increases the mould temperature by insulating the cavity with carbon. Also smoking can block the air from coming out of the vent lines. If you want the cavity coated by smoking, you may need to take a clean rag and wipe off the excess off the vent surfaces so air can escape. The carbon from your match, or whatever you’re using to smoke the mould with, will fill the vents and block escaping air. The carbon will absorb any oils or other contaminants in the mould and usually after a few castings the excess carbon will come out on the surface of the bullets. Setting your mould down on the workbench while casting is another way to reduce or adjust the temperature. The bench surface acts like a heat sink, and takes excess heat away; so if you need to keep your heat up, don’t set the mould down, or borrow one of your wife’s ceramic spoon holders from the kitchen.

The lighter weight cast bullets work best in the Bee, but as I usually do, I try to be contrary and buck the system, and do it my way. Those 65grain Hensley & Gibbs # 62 bullets are probably better in a 22 Savage High power or even a 220 swift. Something with longer case neck and faster twist barrel to better stabilize them. It’s heavy (65 grains) like Ideal’s old 62 grain 228367 but its nose profile isn’t spire pointed. One trick I’m planning on working more with is sizing them both nose first (Figure 3) and bumping it up a bit to shorten it’s over all length and increasing it’s nose diameter like I do with my deer hunting bullets, or using a round nose punch. Deforming the noses rarely if ever changes bullet performance too much. After all it’s the combination of rifle twist, the length of the bullet, its weight and the velocity that determine if it’ll stabilize in your barrel. Run them in the sizing die nose first, then turn them around and lube as you normally would or just simply use a round or flat nose punch. Learning how much pressure to apply when nose sizing is gauged by watching how far the punch goes into the die. It’s a simple technique, but adds another step in your handloading. The diameter of both bullets are a bit oversize, but still can be sized down without any problems. Lyman’s little 225438 isn’t an exact copy of the original Ideal 225438. The Ideal has two tiny grease grooves where Lyman opted for one that is much easier to cast.

Figure 3: There’s more than one-way to skin a cat. Nose first sizing, shown here, will give you another try with a bullet that’s seemingly too long or too pointed for your gun. For lever gun shooters, it’s a way to get your gun going with a flat nosed magazine friendly bullet.

Winchester factory ballistics list pressure of 43,850 psi, and velocity now at 2760 FPS, and I’ve pushed lead bullets in my .218 Bees past that with bullets made out of just wheel weights plus a tiny bit of tin and didn’t get barrel leading. A lead bullet takes less pressure to get the same velocity as a jacketed bullet of the same weight. At the higher velocities, groups were only 3” to 8” depending on bullet used. At what I consider max, 10.5 grain of 4759, that Model 43 came up with a 2.5” group as cast with the Lee Bator. I still want to work with it some more. An unexpected surprise popped up while testing. The lightest bullet wasn’t the fastest while my chronograph was still working. Going up to 2925 FPS, the 47 grain H&G bullet still didn’t lead the bore. In fact at no time did I run into leading problems, and that’s using wheel weight alloy with just a bit of tin to get complete fill on all moulds. The little 255438 got up to 2840 FPS under 12.5 gains of 4227 and still grouped 4”. I did at first size all bullets .224” after finding .225” in the same loads just wasn’t good enough. Speaking of sizing, later I tried a test of 4 different sizing dies, .222”, .223”, .224”, .225”, with the 22596 bullet, and C.E. Harris’s recommended 9.2 gains of 4227 powder. The .222” and the .224” out shot the other two by 2 to 1. This wasn’t a fluke, as I tried it with the 224450 and the same basic results showed up. Why? You got me. Guess that’s another reason to test loads.

.218 Bee Cast Loads Tested for this Article

|

Bullet |

Sized Dia. |

Weight

|

As cast Dia.

|

Powder |

Weight |

Velocity |

Group

|

|

Lyman 225438 |

.224 |

41 |

.228 |

IMR 4227 |

7.5 |

1680 |

1” |

|

|

.224 |

|

|

IMR 4227 |

12.5 |

2840 |

3.75” |

|

|

.224 |

|

|

WW 680 |

12 |

2520 |

3” |

|

|

.222 |

|

|

H-322 |

12 |

|

*1.75” |

|

|

.224 |

|

|

AAC5744 |

14 |

|

1.5” |

|

Ideal 225438 |

.223 |

|

.226 |

IMR 4227 |

9.2 |

|

5.50” |

|

|

.224 |

|

|

WW680 |

11 |

|

*4” |

|

|

.224 |

|

|

IMR 4227 |

9.2 |

|

4.5” |

|

A 224-525 HP |

.224 |

44 |

.225 |

WW680 |

12 |

2520 |

1.25” |

|

|

.222 |

|

|

H-322 |

12 |

|

*2.50” |

|

|

.223 |

|

|

H-322 |

12 |

|

*2.40” |

|

|

.224 |

|

|

H-322 |

12 |

|

*3.25” |

|

A 224-525FN |

.222 |

45 |

.225 |

H-322 |

12 |

|

*1.00 |

|

|

.222 |

|

|

Green Dot |

5.3 |

|

*4” |

|

|

.223 |

|

|

Green Dot |

5.3 |

|

*3” |

|

|

.224 |

|

|

Green Dot |

5.3 |

|

*1.25 |

|

|

.222 |

|

|

IMR 4198 |

12 |

|

*2.25 |

|

|

.223 |

|

|

IMR 4198 |

12 |

|

*4” |

|

|

.224 |

|

|

IMR 1498 |

12 |

|

*2.25 |

|

|

.224 |

|

|

WW680 |

12 |

2430 |

2” |

|

|

.222 |

|

|

WW680 |

11 |

|

*2” |

|

|

.223 |

|

|

WW680 |

11 |

|

*4.50 |

|

|

.224 |

|

|

WW680 |

11 |

|

*1.25 |

|

H&G #4 |

.223 |

46 |

.226 |

IMR 4227 |

9.2 |

|

1.50” |

|

|

.224 |

|

|

IMR 4227 |

9.2 |

|

3.50 |

|

|

.224 |

|

|

IMR 4227 |

10.5 |

2450 |

2.75” |

|

|

.224 |

|

|

IMR 4227 |

11.5 |

2610 |

3.50” |

|

|

.224 |

|

|

IMR 4227 |

12.5 |

2925 |

4” |

|

|

.224 |

|

|

WW 680 |

10 |

2130 |

4” |

|

|

.224 |

|

|

H-322 |

12 |

1940 |

1.25” |

|

|

.224 |

|

|

IMR 4759 |

11 |

|

5” |

|

|

.224 |

|

|

AAC5744 |

12 |

|

4” |

|

22596 |

.224 |

49 |

.2255 |

IMR 4227 |

10 |

|

3.5” |

|

|

.224 |

|

|

IMR 4759 |

9.5 |

|

4” |

|

|

.224 |

|

|

AAC5744 |

12 |

|

2.5” |

|

|

.222 |

|

|

IMR 4227 |

9.2 |

|

1.75” |

|

|

.223 |

|

|

IMR 4227 |

9.2 |

|

3.50” |

|

|

.224 |

|

|

IMR 4227 |

9.2 |

|

1.75” |

|

|

.225 |

|

|

IMR 4227 |

9.2 |

|

3.75” |

|

|

.224 |

|

|

RL #7 |

14 |

2670 |

1.50” |

|

|

.222 |

|

|

H-322 |

12 |

|

*2” |

|

225450 |

.224 |

49 |

.225 |

IMR4227 |

10 |

|

3.5” |

|

|

.222 |

|

|

IMR 4227 |

9.2 |

|

2.50” |

|

|

.223 |

|

|

IMR 4227 |

9.2 |

|

4.0” |

|

|

.224 |

|

|

IMR 4227 |

9.2 |

|

2.50” |

|

|

.224 |

|

|

H-322 |

13 |

2250 |

5” |

|

|

.224 |

|

|

AAC5744 |

13 |

|

1.75” |

|

Lee Bator |

.222 |

51 |

.227 |

Green Dot |

5.3 |

|

*11” |

|

|

.223 |

|

|

Green Dot |

5.3 |

|

*4.50” |

|

|

.224 |

|

|

Green Dot |

5.3 |

|

*4” |

|

|

.224 |

|

|

IMR 4759 |

10.5 |

|

2” |

|

|

.224 |

|

|

AAC5744 |

12 |

|

2” |

|

|

.224 |

|

|

H-322 |

14 |

2290 |

10” |

|

225415 |

.222 |

51 |

.227 |

Green Dot |

5.3 |

|

*1.25” |

|

|

.223 |

|

|

Green Dot |

5.3 |

|

*3.75” |

|

|

.224 |

|

|

Green Dot |

5.3 |

|

*4.25” |

|

|

.222 |

|

|

IMR 4198 |

12 |

|

*4” |

|

|

.223 |

|

|

IMR 4198 |

12 |

|

*4” |

|

|

.224 |

|

|

IMR 4198 |

12 |

|

*1” |

|

|

.224 |

|

|

IMR 4227 |

10 |

|

2.75” |

|

|

.224 |

|

|

H-322 |

12 |

1975 |

3” |

|

|

.224 |

|

|

IMR 4759 |

9.5 |

2190 |

2.5 |

|

225462 |

.222 |

55 |

.226 |

H-322 |

12 |

|

*2” |

|

228367 |

.224 |

63 |

.230 |

IMR 4227 |

10 |

|

22” |

|

|

.222 |

|

|

Green Dot |

5.3 |

|

*12” |

|

|

.222 |

|

|

H-322 |

12 |

|

*6” |

|

G&G #62 |

.222 |

65 |

.227 |

H-322 |

12 |

|

*14” |

|

|

.224 |

|

|

H-322 |

14 |

2427 |

5” |

|

|

.224 |

|

|

IMR 4759 |

10.5 |

|

2.5” |

|

|

.224 |

|

|

IMR 4227 |

10 |

|

20” |

- Indicates groups fired with the Martini

Loading data comes tuff when you’re researching for the Bee. You’d be safe using maximum .22 Hornet loads as a start if you’re in doubt of where to begin. Lyman lists mostly shotgun powders in their cast bullet handbooks, and as you can see by the above chart, I have hardly begun to explore that realm yet.

Toward the end of this project, I had the loan of a converted .22 rim fire Martini re-chambered to .218 Bee (Figure 4). After shooting quite a number of test loads, I’m not certain that knowing the exact bore diameter means much. Shooting three different sized bullets with everything else being the same showed conflicting results. Sometimes the better groups showed up with smaller sized bullets and sometimes not. Years ago I came to the same conclusion trying a .30-06 trying exact loads with 4 different bullet sizing dies. Makes you wonder if authors of cast articles are book readers and not experimenters when they tell you to “slug the bore”.

Figure 4. 218 Bee Martini with .22 rim fire barrel

Experienced reloaders know you’re apt to have the same problems with jacketed while trying to find that sweet spot by changing powder or bullets. Some guns are fussy what you feed them; so don’t get discouraged loading cast bullets. Who knows you may just stumble onto a keeper load that no one has tried yet.