The Model 1 Casting Pot

© 2014 Thomas C. Dugas

See Disclaimer at bottom of page

![]()

(Pot

Constructed Circa 2006)

Part I

I am building a new casting pot, and

wanted to document my experience for all to see.

Why am I building my own pot when I can

purchase a Lee or Lyman pot? I wanted a pot that held at least 100 lbs of lead,

and also could be foot activated for production purposes.

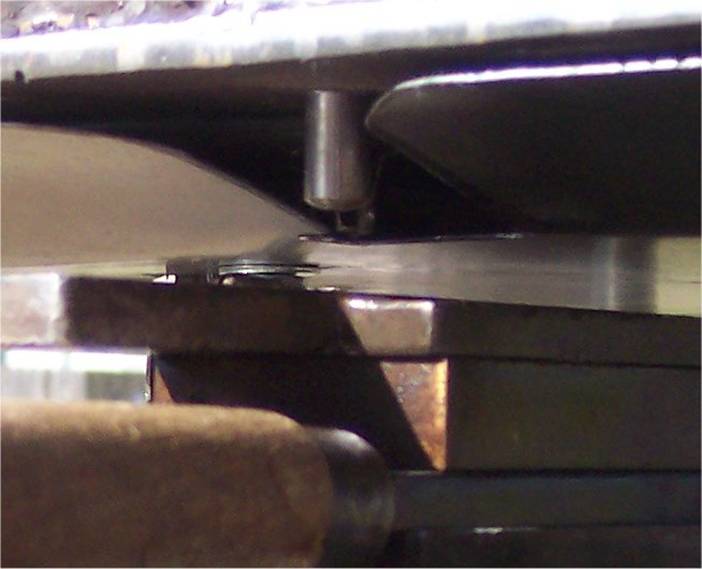

What I am trying to construct is an improvement over the pot I have used for many

years. Here is a photo:

This pot works great, but has a few faults. One of which is that it takes way

too long to heat up for use. Half filled; it takes about 2 hours for the pot to

come up to temperature. And the other point was that it was a loaner from a

friend that I knew he would want it back one day (and he did). That fact, and

along with the other problems I have had with it, I decided to build an

improved (I hope) design.

Here are the materials laid out:

Last week I concentrated on getting all the raw materials. Here is a list of

materials, and their associated cost. I will add more materials as I purchase

them.

$25 - 12" x 12" x 3/8" Steel Pipe Section (I cut this in half

for my pot)

$25 - 13" W x 60" L x 1/4" Steel Plate

$45 - 3 - 6" 1500 Watt Electric Range Elements

$45 - 3 - Maytag Ceramic Element Connectors

$12 - 2 - 5/8" x 24" All Thread Rod

$11 - 26 - 5/8" Hex Nuts

$ 7 - 1 - 3/8" x 24" Angle

Iron

$10 - 1 1 1/2" x 24" Angle Iron

$ 6 - 2 - 3/8" Round Rod

$25 - 1 - 220V Switching Relay (Part of Temperature Control

$32 – 1 used Partlow

Temperature Control (eBay)

$10 - 3 - LEE 20lb Pot Spouts (I need 3 to ensure spares)

$20 - #10 Electrical Wire

– 10 Feet

$25 – Cutler Hammer 30A Fuse Box

$25 – Misc Small parts (electrical

connectors, grommets, Female connectors, shrink tape, wire wrap)

$10 - 2 - LEE 20lb Pot Spout Rods

$25 – Three

3/8” “Yoke” Connectors

$50 - Consumables (Welding Rods, Grinding Pads, etc...)

___________

$408.00 Total

(approximate cost)

The

tools I used:

Oxygen/Acetylene

Cutting Torch

4 ½” Ryobi

Grinder

220V/50A

Miller Arc Welder

110V/15A

Sears Roebuck Arc Welder

Drill Press

Hand Drill

Tap & Die

Set

Hacksaw

File

Sanding Paper

Dremel Tool (cutting

wheels, sanding wheels, etc…)

Safety

Glasses (Clear, Green Colored for metal cutting, dark arc welding glasses)

Safety

Goggles

Full Face

Safety Shield

Leather apron

for welding

Leather

welding gloves

6013 3/32”

welding rods

6011 1/8”

welding rods

7018 1/8”

welding rods

Pliers

Lockjaw

pliers

Welders chalk

Tape Measure

Metal Square

Starrett Calipers

High Speed

Steel (HSS) drill bits

Wood cutting

band saw or jigsaw

Misc.

Wrenches & Crescent Wrenches

This week I cut the 12" x 12" pipe section in half. My pot

dimensions are 12" Diameter, 5.5" tall, by 3/8" thick. I also

cut the bottom plate and the top shelf plate. This is what they looked like

after grinding all the pieces:

One way of fitting the top shelf

to the pot is to follow these instructions.

If you notice, the top shelf needs to have its inner curve match that of

the steel pipe for a nice close fit for welding. Since I used an acetylene/oxygen cutting

torch to cut the two pieces for the top shelf, the inside curved edge was

pretty ragged.

The way I fit it was to take the rough

cut inner part and try to scrape it back and forth over the curve of the

pot. Since the outside of the pot was a

little rusty, this “sawing” action, rubbing it back and forth over the pot,

make nice scrapes on the inside curve of the shelf. I simply ground these high spots with a 4 ½”

grinder, and repeated the process over and over until I had a nice close fit as

pictured below. Here is a drawing of

what I did to fit that shelf to the pot:

The red spots on the inner curve

represent high spots that would get scratched up from the back and forth

rubbing. Grinding these high spots, and

only these high spots, slowly makes the shelf fit the “curve” of the pot.

Today I completed tacking the top shelf, the pot, and the bottom plate

together. Here is a photo with a 16oz bottle of coke for scale:

This weekend I expect to do the welding on the pot base, shelf, and anywhere

else it needs.

Here is a photo of testing out the element placement:

![]()

Here is the result:

I have about 48 photos on my web server showing the progress of construction.

Here are the links to those photos, you can click on each photo for a larger picture:

The next step I will drill and tap the spout hole and begin assembly of the

temperature control mechanism which will consist of the following parts:

Partlow 0F to 1000F Temperature control thermostat

220V Switching relay

Individual on/off switches for each heating element [deleted]

On/Off switch for Whole Unit

Small Switchbox with 30A Circuit breaker.

Cord and plug to tap into a 30A dryer outlet

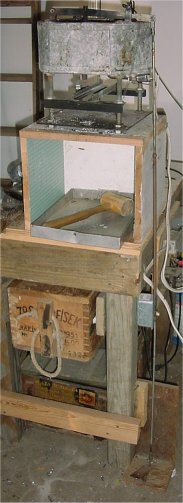

The Pour Spout

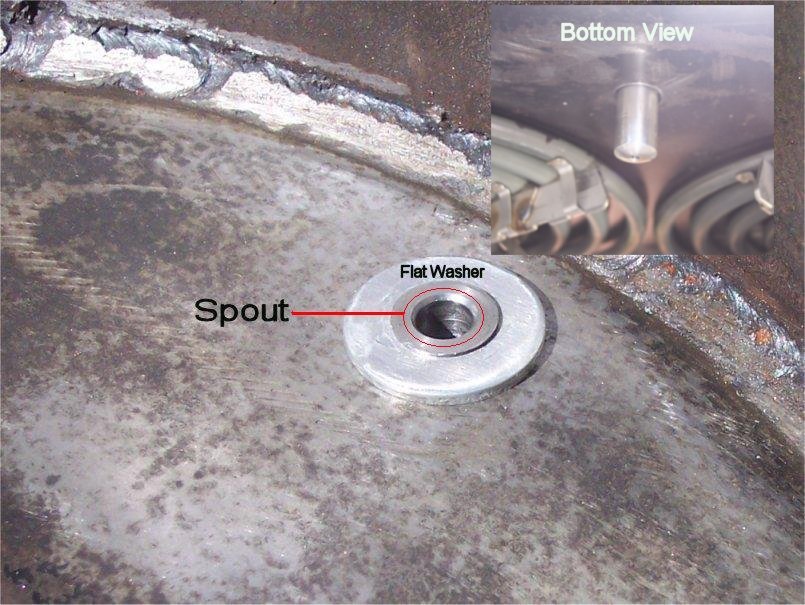

After much thought, I decided not to

reinvent the wheel and try and use off the shelf components where I could.

Lee makes some pretty good pots, and I

was able to access their spare parts page online. I noticed that they sold

the 20lb. spout and rod as separate parts. So, I

ordered three of each.

The problem is that Lee only threads

about 1/4 to 3/8" of the spout. To raise the spout off of the pot floor

and create a "ledge" to keep dirt out I used a flat washer bored out

to act as a step. This raised the height of the spout by one washer thickness.

Which, isn't much, but its

better than having the spout level with the floor of the pot. I would use two

washers, but I don't think I will have enough thread left on the spout to

engage.

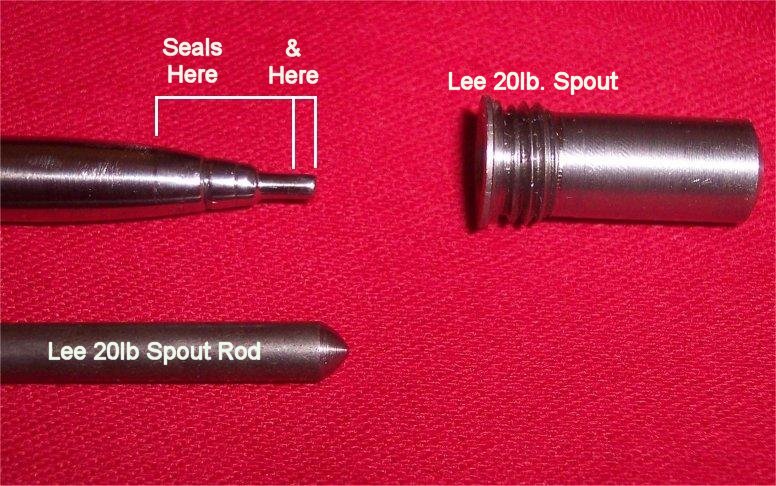

I was happy with the spout, but disappointed with the rod. The rod looks almost

like an afterthought.

So, time to make my own rod.

Here is the result:

The lee rod is at the bottom (above photo). My new rod is on top. It seals at

both the tip end on also at the flange end. I prototyped the inside of the

spout with a wax cast to see what a rod SHOULD look like.

This is the wax cast:

My rod is not nearly what the wax cast is, but patient work on the drill press

with 600 grit sandpaper, a caliper, a Swiss flat needle file, and patience,

patience, patience revealed two sealing surfaces on the new rod. The stock

material (the new rod) was found rolling around the bottom drawer of my tool

box. I think it’s a leftover handle from those kits you buy to take off

bathroom water spigot valves, it’s the handle part. Any good steel round stock would be candidate

material.

The Pour Spout is

continued here

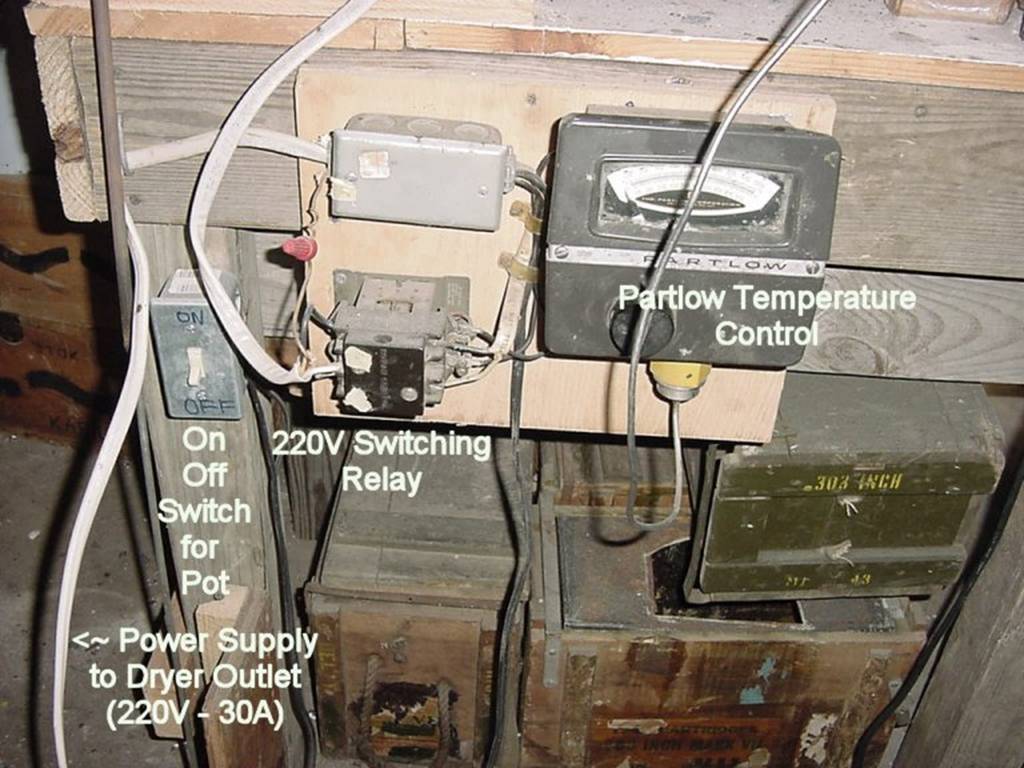

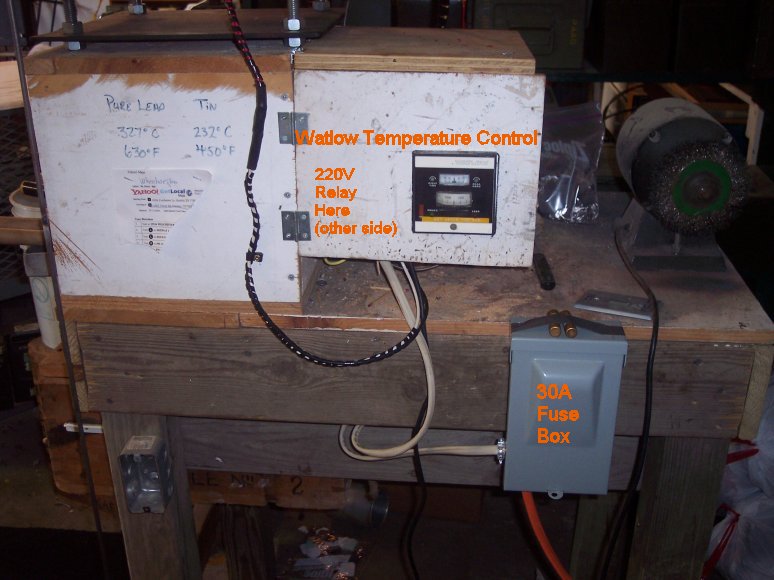

Here is a photo of my current electrical setup. It

uses a 220V switching relay (made in 1962 according to the stamp on the side) its a Partlow

Zero Degrees Farenheit (0F)

to 1000F temperature control, and miscellaneous wiring.

I could use rheostats off of a stove to control temperature, in fact, I was

thinking about that today. That would truly be the low cost option, as the Partlow temperature control is about $250 (ouch!). I

thought that by using a casting thermometer, I could fine tune and calibrate

the rheostats to discover which combination of settings would translate to a

corresponding melt temperature. I

decided that rheostats were a dead end.

I want automatic temperature control.

The Partlow control, pictured above once set up, does

its job, switching the relay on and off to keep the temperature where it needs

to be. The rheostats are an attractive lower cost option, but would always need

to be on. There would be no "off" while casting unless I messed with

them.

Part II

Thanks to a touch of insomnia, I spent the last few hours on eBay and

discovered that temperature controllers can be had pretty inexpensively. I even

found the exact same model as pictured above (the Partlow

MF-4) which is obsolete and discontinued. It sold for $35! So I’ve decided to invest in either a new

temperature controller (called “PID” controllers”) or

find a cheaper alternative in a used unit on eBay.

I emailed one of the temperature control

vendors and for about $75, I can get a modern digital readout, relay output, K

Type (0F to 1250F) Thermocouple Temperature controller. If I go used, the price

drops to about $50. You can also get a

very good new PID controller from Auber Instruments.

With prices like these, I am not using stove rheostats as temperature

controllers. I just may not use the expensive Partlow

temperature controller if I can find a lower cost alternative (I did end up

finding a used solid state controller on eBay, but if I ever have to replace

it, I am going to Auber Instruments and get one of the new digital ones.

Insulation

I had in the back of my mind that I might need to insulate this pot for better

performance. But until a friend raised the issue, the thought never made it to

the surface. Well, it has. I did a little reading on the internet and

discovered Rock

Wool Insulation. It's used in stoves (old and new), blast furnaces,

boilers, etc... The temperature rating appears to be in excess of 1500F. So,

that is what I will use. My plan is simple, I am going to cover the bottom of

the heating elements with a thin plate of steel (1/8", or 3/16th plate) I

will extend that out past the all thread just enough to allow about 1" to

2" of space past the circumference of the pot base. Then, I hope to use

sheet metal to cover the outside of the pot, leaving 1" to 2" of gap

between the sheet metal and the pot wall. I intend to pack this gap with Rock

Wool Insulation.

This is a quickie drawing of what I am contemplating:

That's the plan so far.

I received some advice when I posted about the pot over on Cast Boolits:

|

Originally Posted by powderburnerr You might want to leave a little

air around the elements .I have repaired a lot of stoves that burn off the

connectors when a big pot is set on them they need air circulation...... Dean |

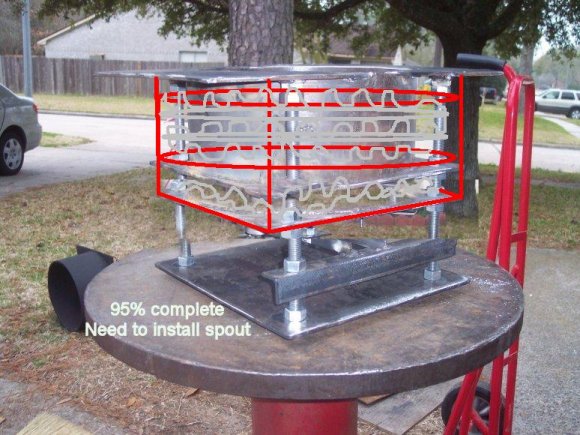

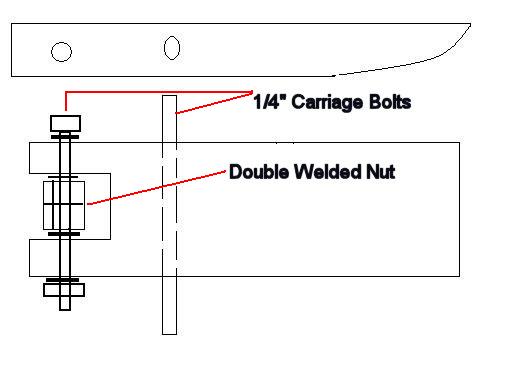

Thanks. This is a quick drawing of what I intend to do with the elements.

The bolts I welded to the bottom

of the pot to hold the elements in place are long enough to place a double nut

on the end, leaving about 1" of bolt sticking out. I will cut the plate to

fit the red square (from each corner of the all thread) and drill three holes

where the red triangle has corners. I will use that 1" of bolt sticking

out to hold that plate in place. I don't think I will use insulation here, just

the plate cover to block the elements should be sufficient.

This

was a dead end. The bolts and the flat

stock didn’t work. I went in another

direction. See below.

I ended up purchasing a Watlow used solid state PID

controller that was made around 1975. I

found it used on eBay. It had all the

elements I needed in a PID controller.

The heating elements are powered by a 30

amp 240 Volt house circuit that normally provides power to my clothes

dryer. To ensure the power to the pot

was within the range of the 240V/30A circuit, I checked the math.

The formula is:

Watts = Amps x Volts (W = A x V)

Since each of the three heating

elements draws 1500 watts @ 240 volts, we have enough to solve the equation.

1500(3) = A x 240

Solving for A gives: 4500/240 = 18.75 (A)

And the solution to Amps = 18.75

amps.

So the three heating elements

will draw 18.75 amps. I have it on good

authority that you should not run a circuit more that 80% of load. So,

80% x 30A = 24A.

24 amps would be 80% of load, so

at 18.75amps I am under the 80% load limit.

So, power to the three 1500 watts

6 inch coil heat elements is solved. I

can use my 30 amp dryer circuit.

The used Watlow

temperature controller needs 120V power.

Easy enough, as any 120V outlet will do.

No problem there.

The used Watlow

temperature controller has one output that is a relay. The relay simply flips between connectivity

on three contacts. With power off,

contacts 3&4 are closed. A

continuity check verified this. When

120V power is applied to the controller, and (note the “and”) a LOAD is

detected, the relay inside the controller fires and closes contacts 4&5,

leaving 3&4 open.

Here is a photo of the rear of

the used Watlow temperature controller. Many modern controllers have a similar

setup. Included also is the 240V 30A

relay that switches power to the heating elements.

Note this is a small photo, click

the following link for a larger easier to see photo:

Note that on my controller, no

power is actually supplied through the relay.

The relay just acts as a switch.

Please note this, as many modern digital controllers also have relay

outputs, but also provide 120V power through the relay (Auber Instruments has many digital PID Controllers that provide this function). This is nice to have. You don’t need to run separate power to the

relay to get 120V power like I had to do on mine. I had to jumper power from contacts 1&2

to get 120V through the relay. I jumpered the “hot” wire on 120V. Not the neutral or the ground. You may not have to do this on a modern

digital relay. All you would have to do

is identify which state the relay contacts are in (open or closed and when) and

run power from those contacts to the big 240V/30A switching relay. Note that the 240V/30A switching relay is

actually powered by a 120V coil, which is how you activate it, and why it needs

120V power to work.

When the 120 Volt coil receives power, it activates, allowing power (in

this case 220V) to flow to the heating elements.

To wire the heating elements, I

was careful to observe color coding on the #10 wire to each heating

element. I ran all the “black wires” to

the left heating element connector and all the white wires to the right heating

element connector. I maintained this

wiring coding all the way back through the relay, and through the 30A fuse box,

and through the #10 wire back to the dryer plug. I connected a ground wire to the little “L”

bracket on the rear heating element. If

you notice, on the heating element connectors, there is usually an “L” shaped

piece of steel, very small, about ½” long either side included with the

connector. This little piece of metal is

normally used to attach the heating element connector to the stove or range

top. Where this part connects onto the

heating element is a great place for a ground wire. The other end of this ground wire was

connected to the solid copper ground wire that was on the 240V power on the

powered side of the relay. In other

words, the pot is always grounded before the big 240V/30A relay fires.

A note on the

30A fuse box. This fuse box is nothing more than a Cutler

Hammer 30 amp fuse box that is commonly installed for outside Air Conditioner

compressors. You can use a fusebox, or a little breaker box with a single 30A

breaker. Either will work fine. I used the fuse box because it was easier to

find, and easy to wire.

Here is where I am now, shielding has been added to hold the Rock Wool

Insulation:

After Buckshot's post regarding insulation (on the original “Cast Boolits

Thread”), I agreed with his thoughts. It can't hurt, and can only improve

the efficiency of the pot. I was able to adapt the design to install the

shielding, sheet metal purchased from Home Depot and cut to fit.

Drilling and Tapping the Pour

Spout

Prior to the heat shielding, I did finally manage to drill and tap the pot for

the Lee 20lb spout. The Lee Spout is threaded 7/16 - 20. Consulting my tap and

die chart, I discovered I needed a letter size drill ("W") to drill

the hole. Another trip to Grainger, the

only place around I can buy a single letter size drill

bit. This chore took half the day on a Friday. I had to disassemble the whole

assembly to get it down to the pot. I then improvised a platform on my drill

press and clamped the pot in place. From the outside in (meaning I drilled the

pot from the outside of the bottom towards the inside of the pot) I drilled the

hole (using the “W” Drill Bit), and then removed the drill bit without touching

the pot position. I inserted the 7/16 - 20 tap and by releasing the tension on

the drill press, I hand started the tap (Note: No power to the press, I used my

hand to twist the drill chuck manually) with the assistance of the press. I did

it this way to insure a deal straight tap start. Once the tap started, I released

the tap from the press and fitted a hand tap handle and proceeded to tap the

hole manually after that.

I then released the pot, and hand stoned flat the ridge inside the pot created

by the bit coming into the pot. I used a small stone that came with a Buck

Pocketknife. No idea what grit it is (I assume is 100 or 200 grit, give or

take), but I wet the stone, and just patiently worked it back and forth over

the hole until I had a nice shiny flat spot all around the drill hole. I did

the same thing to a flat washer, after boring out the center of the washer to

just under the OD of the spout flange. I finished up both with 600 & 1000

grit wet sandpaper.

Here is the spout installed:

And the water test to see if the mold guide was centered: (it was)

Once the spout and side heat shielding was done, I decided on a design change

for the heating element retainer. Instead of the flat stock (1/2") I had

planned to use, I removed the flat stock and cut to fit a piece of sheet metal

to cover the whole heating assembly, and also to act as a retainer for the

elements. Pictured below:

Flat

sheet metal used as heat shield

Why did I change this? The 1/2" metal flat stock didn’t' work out because

I had to layer another 1/4" nut on top of the nut holding the flat stock

in place to act as a stop for the heat shield that I was installing. I realized

quickly by the time I layered all those nuts, the mold top would be over

2" - 3" from the bottom of the pot spout, making for a long, long

drop for the lead stream. I was worried that with such a long drop, the lead

stream would cool too quickly and I would get all sorts of problems.

So, after taking a break and thinking about the problem, I realized that the

flat stock holding the elements in place could be eliminated in favor of a

piece of sheet metal to do both jobs, holding the elements in place, and also

shielding the heat of the elements.

Here is the finished work:

For the remainder of the day I am working on the foot petal activated spout control.

Here is the finished product:

To see the foot pedal spout control in action, click the following link. This

is a a Quicktime Movie

from my Kodak Digital Camera. The file is approximately 5 Megabytes.

Quicktime

Movie of the Spout Control

Here is a URL list of the photos of today's work:

Checking that the Spout is centered

Directly over the center of the mould

Start the work on the spout/foot pedal

activation

assembly. The throttle

bracket is just resting

on top of the pot at the moment.

I fashioned a foot pedal assembly by

bending flat stock

And “eyeballing” the

design as I progressed.

Using a big “C” clamp to hold the flat

stock in place while

I test the function before tack welding.

Tack welding the support and throttle

clamps in place…

Close-up of the welding…

Close-up of the inside of the pot

showing the pour spout, and the “rig” I used

To suspend it to the

foot pedal assembly (the flat stock). Notice how everything

More photos of the welding…

Starting to paint with flat black high

temp paint…

This out of focus photo was a test of

the mould height with a 8 cavity mould.

The washer on top of the mould sprue

stop screw was used to set minimal

Clearance on the mould

guide.

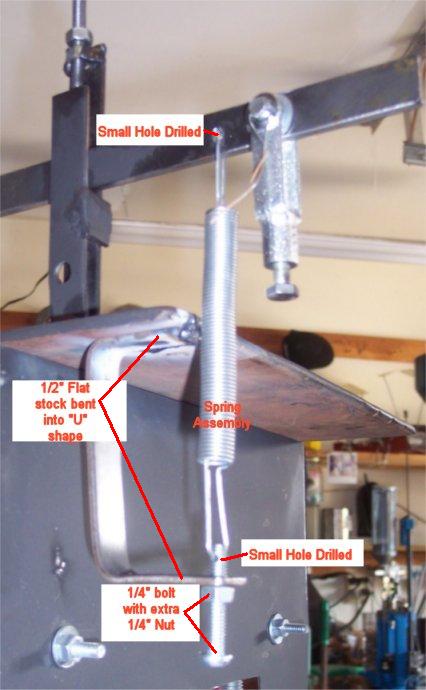

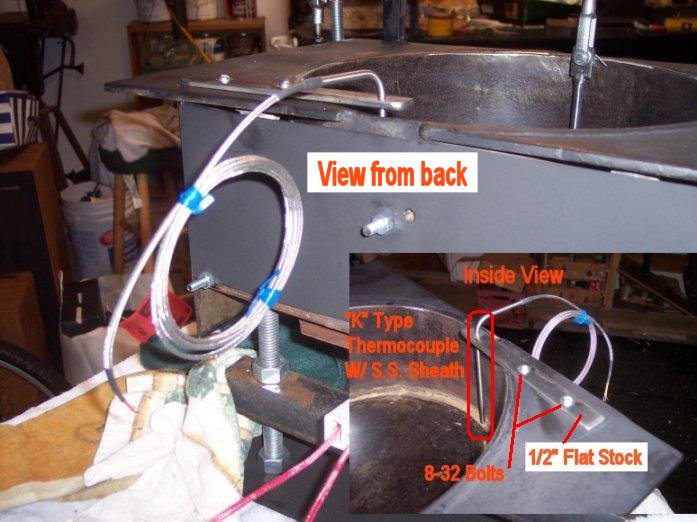

Today’s work was fabricating and

installing the spout lever spring return.

There are photos above and below showing the work. The spout rod needs

opposite force in the form of a spring to ensure that the spout rod positively

returns to the spout hole. I found a spring in the size and shape that I needed

at a local ACE Hardware store in one of those displays that has about 100

different styles of springs on a display board.

I fabricated a little bracket out of leftover 1/2" flat stock with a

hammer and a vice. The bracket was hammered into a large "U" shape

and welded to the underside of the pot top after modifications were complete. I

drilled a hole in the bottom leg of the "U" and tapped it 1/4" -

20. I then found a 1/4" - 20 bolt and ground a little flat side near the

end of the threads and drilled a small hole to accept the spring wire. Since I

was drilling on threads, the flat spot is necessary to get the drill bit

started, otherwise, the bit walked all over the threads. I drilled a small hole

in the 1/2" flat stock foot actuator assembly to accept the other end of

the spring. The 1/4" - 20 bolt will allow me to adjust the spring tension

by screwing the bolt in or out. The extra 1/4" nut will lock the bolt in

place once its set.

Here is the photo of the finished work:

Took about an hour for this part of the job.

Here is the photo of the finished work:

Today

was spent fabricating the foot pedal assembly. I had a hard time with this one,

but in the end it turned out OK.

I initially tried to duplicate my old foot pedal, but since it was made

entirely out of iron, and was on the small side, I really wanted to use off the

shelf parts. Problem solved at Home Depot. I found a galvanized reinforcing

sheet metal piece that is used to reinforce deck 2 x 4's. Here is a photo of

the piece, unmodified:

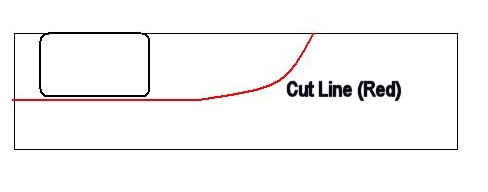

Since it was created to fit over a 2 x 4 (edge on) I slipped it over the edge of

a 2 x 4, traced its outline, and then made a gentle curve from the inside line

out to the edge of the 2 x 4. Something like this:

This piece of curved wood would become the foot pedal.

I next took a short (about 8" or so) piece of 1/2" flat stock and

bent it into a wide "U" shape. This would be the bracket to hold the

wood & sheet metal foot pedal to the "L" shaped board (more on

that later).

I notched the opposite end of the wood slice out of the 2 x 4 to create a gap

for a double 1/4" nut that I had welded together (poor man's collar).

Here is a drawing of that:

This was really a one-off, go-by-feel type of thing, so I won't go into more

detail into how I built it. Here is the finished product:

Here is a slightly different angle that shows the "U" shaped bracket

better:

The assembly was bolted to a 7" wide "L" shaped piece of wood as

seen in the above photo. This will get screwed to one of the front legs of the

table where the pot will be placed.

Here is a short Quicktime movie of the foot pedal in

action, it's about 2MB:

Short 2MB movie of the Foot Pedal

The final 5% of work proved to be challenging. Last week I received the Watlow (made in 1979) PID

temperature controller I purchased on eBay. It took a few days for me to figure

it out, and how it worked. I grew to like this temperature control, on the

inside it looks like a High School science project, with relays, resistors, pot

controls, etc... REALLY easy to work and repair these, as you will see later in

this post.

Once I figured out the temperature control, I decided to create a control area

at the rear of the pot to house all the electrics. Here is what I ended up with:

The Watlow is a very simple temperature control. The

dial ranges from 0F to 800F and uses a "J" type thermocouple. There

is a range window above the temperature control wheel that shows action 50F

above and below target temperature range. The relay inside the temperature control

activates when the range setting hits the center. It seems to work pretty well

for a nearly 30 year old control. On this particular model, the relay simply

flips between open and close on three contacts. Contacts 1 & 2 are normally

closed, and when the relay fires, 2 & 3 are closed, 1 & 2 are open. So

I decided to use this relay (inside the temperature controller) to control 110V

to the other 220V 30A relay that I had purchased. It worked fine.

Finishing up the pot called for installing the foot pedal and welding the round

rod to the top of the pot. Here is what it looks like finished (warning - the

link is a BIG photo)

Link

to larger photo

After I finished welding the round rod extension (basically I was connecting

the gap between the round rod from the foot pedal to the round rod that was

hanging from the turnbuckle attached to the spout control) I decided to add

some reinforcing to the wood stand that holds up the pot. Don't have photos of

this, but I had some leftover oak 1" planks and these were cut to fit

alongside the wood box. Once cut, they were gorilla glued and screwed into place

to provide additional support for the pot.

After everything was hooked up and checked for the 10th or 11th time, I decided

to plug it in and see if it worked.

And.........it didn't.

The relay in the temperature control was firing, but the big 220V relay wasn't.

It's not hard to miss as it makes a loud "clunk" when it opens and

closes. I pulled the temperature control apart (the inside just slides right

out of the box) and discovered a broken wire on the relay contact. It was an

old repair, and the wire had been jarred loose. Yah! I got to use my soldering

iron. Popped it back in and the big 220V relay fired right

away.

But, no joy on the heating elements.

I was only getting 110V to the heat elements. Unplugged everything and checked

again. Starting running continuity checks on the wiring and discovered that the

little 30A fuse box I installed had a fuse that was seated cockeyed. The

bracket holding the fuse must have gotten bent (opened up) when I was

installing the box and the fuse wasn't making contact with one of the circuit

legs. Once that was fixed, plugged everything in and .....SMOKE!

Started getting smoke off of everything on the pot.

Residual oil from construction, etc.... Let the temp come up to about 400F or

so and the smoke disappeared.

I didn't melt any lead tonight, just wanted to verify that the pot worked.

Tomorrow, I will start testing the pot with lead to see how long it takes to

melt a 50% load of lead.

I consider the project complete. I want to thank everyone for their

advice and comments as I went along building this project.

Limitation of Liability

You understand and agree that under no situation will we be liable for any

direct, indirect, consequential, incidental, special or exemplary damages for

any use of this site or any linked contents, even if we are advised of the

possibility of such damages. Your only remedy is to discontinue use of this

site. You waive the rights of lawsuit for any damage happened as a result of

the use of this site.

If you

do not agree, please leave this website.

Click here to leave the website

The

activity described below is inherently dangerous. This page described the detailed construction

of a pot for casting with lead, a known carcinogen. Melting lead is an extremely dangerous

activity which may result in bodily harm, up to and including severe burns

and/or death.

This

information is provided without warranty of any kind. No guarantee is made for any of the

information posted.

Use of

this site is at your own risk.

![]()

Back to the

Bullet Casting Central Page