75,000

Wadcutters in a Model 27

© 2014 Thomas

C. Dugas

I like wheelguns. Be they Smith & Wesson, Colt, or Ruger, I’ve always had a fondness for blue steel revolvers

and their later cousins in stainless steel.

Because I like revolvers, I like to shoot them quite a bit, but even for

a Model 27, a steady diet of full power .357 magnum loads usually results in a

shorter life for the gun, and for the shooter.

My favorite load for my wheelguns has always

been target loaded wadcutters. For the

Model 27 I started with factory loaded wadcutters in the late 1980’s, before I

had the reloading bug. I shot factory

ammo for years before I decided I needed to “roll my own” and enjoy the savings

and benefits of my reloads.

In 1992 I purchased a new 5” Smith &

Wesson Model 27-2 at a local gunshow. The revolver came in the wood box with the

cleaning rod, screwdriver and other usual accompaniments. As I was known to do in those days, I

carefully ground down the grooved target trigger and slowly polished the face

to a smooth mirror shine. Following the

careful well-written instructions in Kuhnhausen’s

book on Smith Revolvers, I slowly and carefully smoothed the action. The rear leaf sight was changed to bottom the

rear sight for the loads I intended to use.

The last refinement was a set of Pachmayr

rubber grips that fit my meaty hands rather well.

For the next few years I shot a variety

of loads with this revolver, coming to love the big N frame and the slow

improvement of its double action pull. I

grew accustomed to, and then mastered the double action trigger. Most of my loads in those early years were a

mixture of factory ammunition and handloads. An early favorite of mine was the Skeeter

Skelton .38 Special Load. The Lyman

358156 Gas Check cast Semi-Wadcutter over a hot load of 2400. It was an accurate load, but wearing on the

shooter over extended shooting sessions.

Enter the factory wadcutter

loads. A shooting friend had a stash of

Winchester Western (WW Headstamp) .38 Special factory

wadcutter from his competition shooting days. After a short negotiation, I owned his

stockpile. In the N frame, the factory wadcutter loads barely moved the big revolver, and I could

shoot hundreds of rounds each session.

But soon, I exhausted the stockpile and was left with just the

brass. A quick search of my Lyman

reloading manual revealed a suitable load for the brass. I needed to reload.

At about the same time my reloading

setup matured. I had restarted casting

bullets again after a long hiatus. I also rekindled my love affair with Hensley

& Gibbs bullet moulds. When I was a

crew cut wearing kid in South Louisiana, my first exposure to reloading and

shooting was when I was introduced to bullet casting by a sheriff’s deputy. He carefully taught me to cast .38 Special

Wadcutters with a 10 cavity gang mould and a ladle. It was slow going, but in those days, I had

plenty of time between customers at my dad’s service station, so casting

bullets was an enjoyable pastime. It also

didn’t hurt that I was friends with the local Law Enforcement community, a

relationship that later helped tame my wild teenage years. That big gang mould spewed bullets like a

ripe pea patch. Oddly, I didn’t shoot the ones I cast,

they were traded over a summer for my first revolver, a brand new Smith &

Wesson Model 14-4, which the deputy gave me late one August evening. It was the beginning of a lifelong love

affair with wheel guns. And cast bullets.

When I renewed my interest in casting in

the 1990’s, I remembered that big 10 cavity Hensley & Gibbs mould I used as

a kid. In a fortunate combination of

events, eBay was going strong and I was able to quickly find a perfect

condition 10 cavity #50 in plain base. Thus began my wadcutter

reloading. I decided to be methodical,

and carefully worked up a load that shot accurately in that 5” Model 27. I also corresponded via email with a few

shooters, and discovered the variables that could be eliminated to improve groups. I thought I had reached my goal. Little did I know.

For the rest of the 1990’s I enjoyed

acceptable accuracy with my cast reloads.

When I moved to Northern Virginia in 2008, I discovered a neighbor whose

vast experience with cast bullets, reloading, and other subjects dwarfed my own

knowledge. Ed Harris kindly mentored me

when I explained my success with my own reloads, and he gave me the knowledge I

needed to improve on what I had. He patiently explained to me how to eliminate

variables and I re-read all of his articles on .38 Special loads. The information was an eye-opener. I still had a lot to learn.

Ed also tutored me. First was the

mastery of tumble lubing with Lee Liquid Alox.

All those years previously I had patiently used a Star Sizer with a .358” die to size and then lube those

wadcutters, one at a time. Ed showed me

how to lube hundreds of wadcutters in about two minutes and allow them to air

dry in about a day or so. A vast improvement on my own laborious technique. I lubed as cast, no sizing. Using a micrometer, I discovered that my 10

cavity mould dropped bullets right at .358”/.359”, perfect to shoot as

cast. Below is a photo of a short

casting session with a 10 cavity Hensley & Gibbs #50 Plain Base:

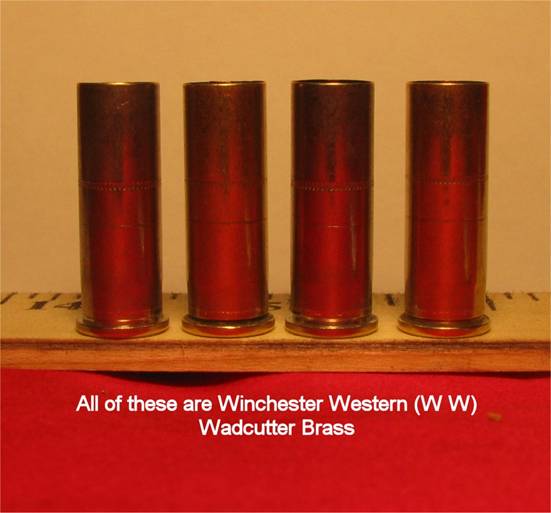

Ed also encouraged me to exclusively use

wadcutter brass, something I had not always

done. I usually grabbed whatever .38

Special brass was at hand and loaded them. Accuracy was mediocre as I later

discovered. I could do much better by

focusing on wadcutter brass. I methodically went through my entire .38

Special brass pile and pulled out all the wadcutter

brass (double cannelure). I was left with two head stamps, Winchester

Western (WW) and Winchester. I went one

step further and sorted the brass and nickel plated WW head stamps into

separate ammo cans.

Click on photo

for larger pic

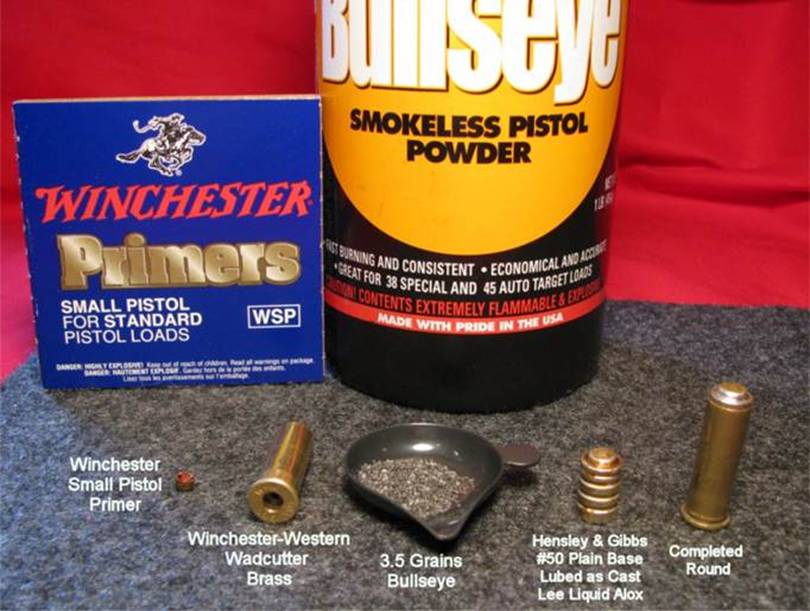

After conferring with Ed, all of the

elements were in place. I had the projectile

(the excellent Hensley & Gibbs Plain Base #50 Button Nose Wadcutter ~146

grains as cast), the wadcutter case, and the load

(~3.5 grains of Bullseye). I settled

down to load.

Groups immediately began to

improve. Previously, I had been impressed

with 3” to 4” groups at 10 yards. I

thought this was acceptable accuracy for wadcutter

reloads. Using the new recipe, my

average groups began to shrink and my confidence in the load began to

increase. 3” groups were rapidly

becoming the maximum, 2” groups were average.

On some long strings of fire, 11 of 12 rounds would go into 1.5”. The more I shot, the better I shot. Moving the target closer to 7 yards closed

the groups dramatically. I used a

homemade cardstock target with a 1” round circle as the center bull. I routinely began to excise the center bull

with strings of fire.

One evening I was shooting at the local

range with Ed and he encouraged me to move the target out to 22 yards, the

maximum for that range. I was hesitant,

I feared I would hit everywhere but the target.

But I tried it and was surprised I could keep 90% of my shots in the 8 ½

x 11” sheet of cardstock. So I kept

practicing. I discovered that shooting

at the longer distance forced me to address sloppy shooting techniques that I

ignored at 10 yards. Front Sight…front

sight….squeeze…front sight became a mantra I said to myself over and over. And the groups started to shrink at 22 yards. And become very round. I discovered shooting 300 rounds at 22 yards

to “warm up” improved my shooting at 15 yards when I moved the target

closer. Even better at

10 yards. My routine was to warm

up at 22, then shoot at 15, then 10 and finally at 7 yards. Approximately

400 rounds per session. The load was working perfectly and I “locked it

in” as they say. I decided that this

load was going to be my one .38 Special target load and I wasn’t going to

change anything. Over the years I had

developed a habit of tearing off the Winchester Small Primer box tops and

tossing them into an open .30 caliber ammo can when I

recharged my Dillon Primer tubes. I have

a dedicated Dillon 550B setup for .38 special wadcutter

loading. The last station is a Lee

Factory Crimp die, set to Ed’s suggested specs.

The ammo can began to fill up with cardboard tops.

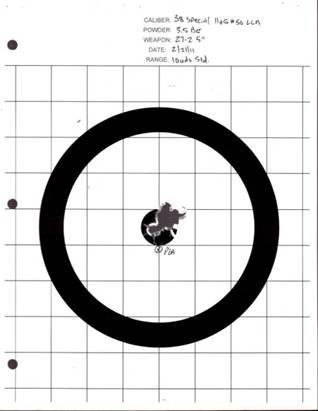

Over the years I’ve shot many 1” groups

at 10 yards with my load. I’ve come to

expect that the load will perform as long as I perform. The following picture is a target I shot in

February 2011 with the same load and the Model 27:

Click on photo

for larger pic

Fast forward to

January 2012. I decided one day to count all those

Winchester cardboards. I counted

810. That’s 81,000 small pistol

primers. My best guess is that about

75,000 of those are 38 Special Wadcutters.

All were shot in that Model 27 I purchased in the early 1990’s.

The action on that Model 27 is now

buttery smooth. The finish shows the

honest wear of hundreds of range sessions and cleanings. I’ve never taken the side plate off since the

original action job. The sights remain

unchanged. It shoots 1” groups at 10

yards all day, every day, each time I bring it to the range. All of the loads I now shoot are of my own

manufacture. Tracking expenses closely, I calculate that each wadcutter load cost me about 7 cents. Good value and well worth my time.

Factory wadcutter

ammunition is one of the most accurate factory loads that can be purchased for

the .38 Special. I’m pleased to discover

that perfectly acceptable accuracy can be achieved by the reloader

using his own components paying careful attention to those factors that improve

the performance of the completed rounds.

I plan to continue to shoot this load in

that Model 27 well into the fall and winter of my life.

Here is the Model 27, well into the fall

of its life. Pictured with another

favorite load, the Hensley & Gibbs #135 Hollow Point (Hollow Point version

of the Lyman 358156GC):

Click on photo

for larger pic

Here are two photos of the forcing cone

area. I didn't realize the lead plating

was so severe until I took the photos. Might be time for a "deep cleaning."

Click on

photos for a larger pic

Back

to the Hensley & Gibbs Main Page